World-class Precision Engineering, Manufacturing & Design Development

Who We Are...

Based in Thirsk, Yorkshire, we are a leading provider of precision engineering solutions, specialising in a wide spectrum of services from bespoke CAD design to additive manufacturing. Our team of highly skilled engineers and technicians works to the highest industry standards, using CAS, CAD, and CAM software to guarantee product satisfaction. Our approach allows us to efficiently handle complex engineering tasks with the utmost precision, ensuring that every product meets or exceeds your specifications.

We place a strong emphasis on cost-effectiveness and project timelines. Through smart material management and production strategies, we maximise yield from stock, which helps reduce material waste and lower costs. This also allows us to offer fast turnaround times without compromising on the quality or precision.

Our dedicated team is ready to take on any challenge, providing tailored engineering solutions that meet the unique needs of each project.

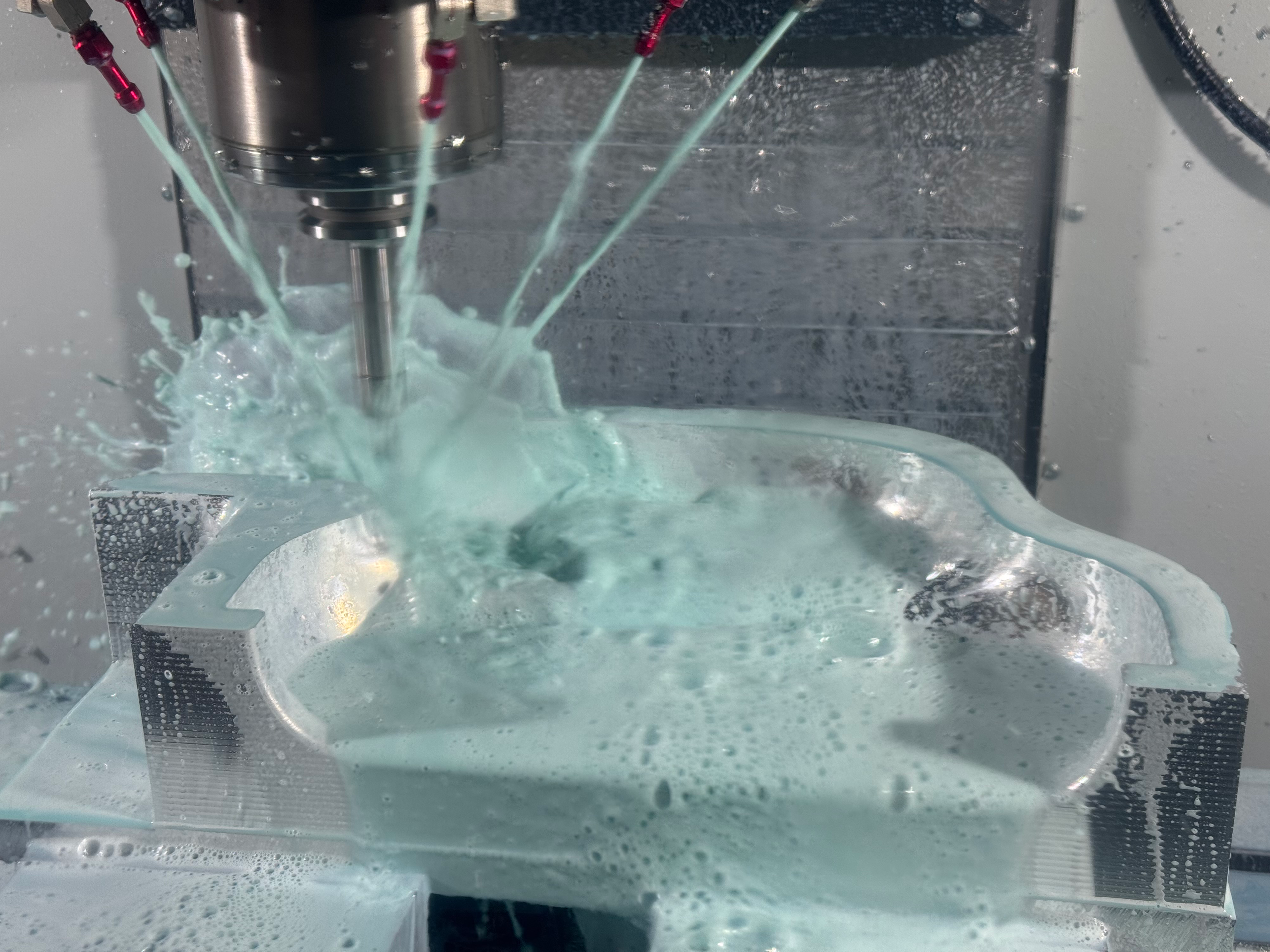

-High Quality Materials and Tooling-

We employ the highest quality materials and tooling across our range of services. Sourcing from the very best suppliers in industry, we can guarantee only the best quality of metals and plastics.

-

We know that customers require nothing short of the highest possible tolerances when it comes to precision machining, that's why we incorporate high quality tooling in our workflow avoiding tool pull-out and large run-outs.

At a glimpse

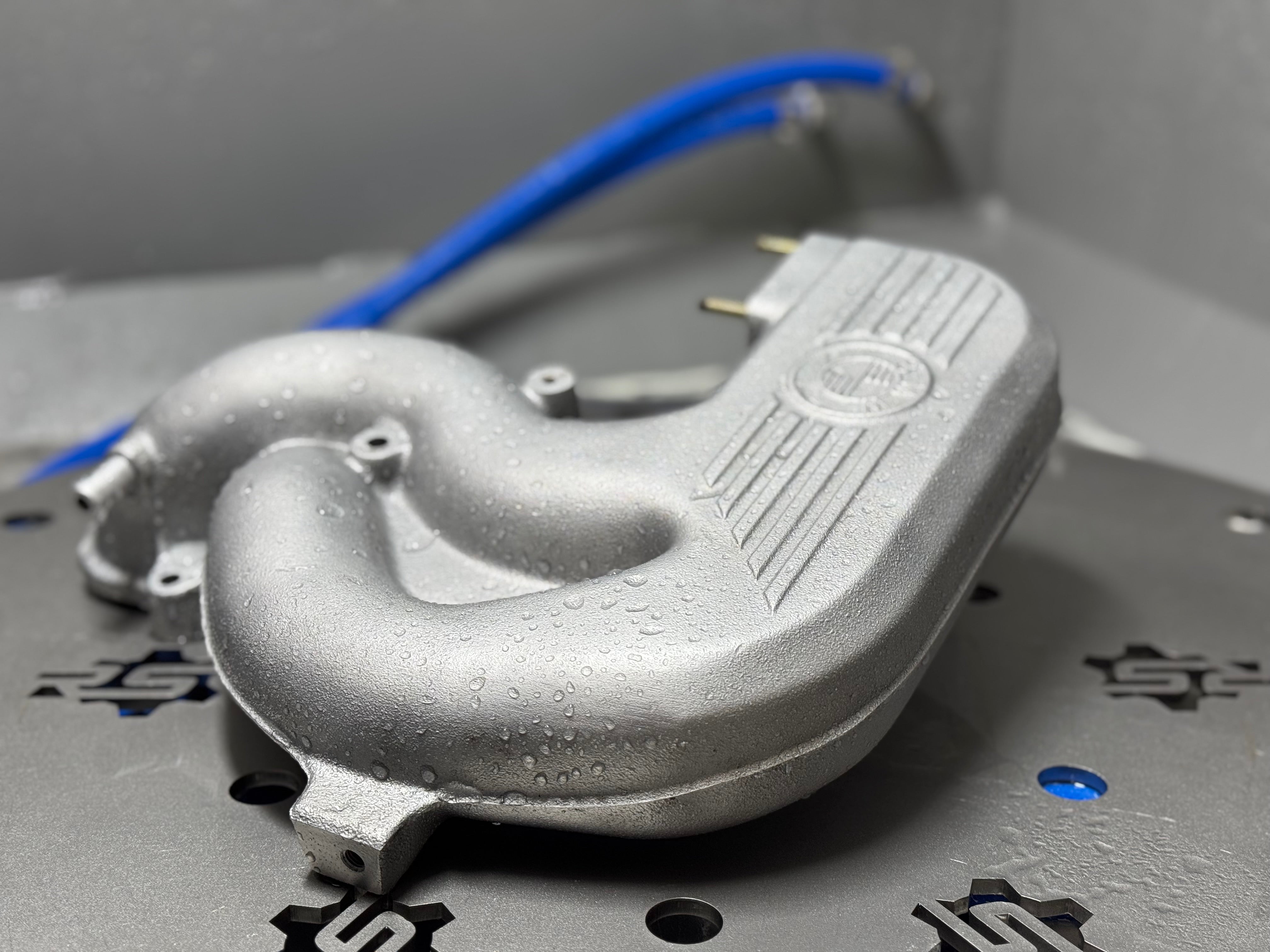

Bespoke Projects

Creating a truly unique and functional product requires an iterative and collaborative approach. At Carraero Engineering, we provide fully customised, end-to-end solutions tailored to your exact specifications.

From the initial concept to the final prototype, our expert design team works closely with you to ensure your vision is brought to life. You’ll have direct access to our specialists throughout the process, ensuring alignment with your functional and aesthetic requirements.

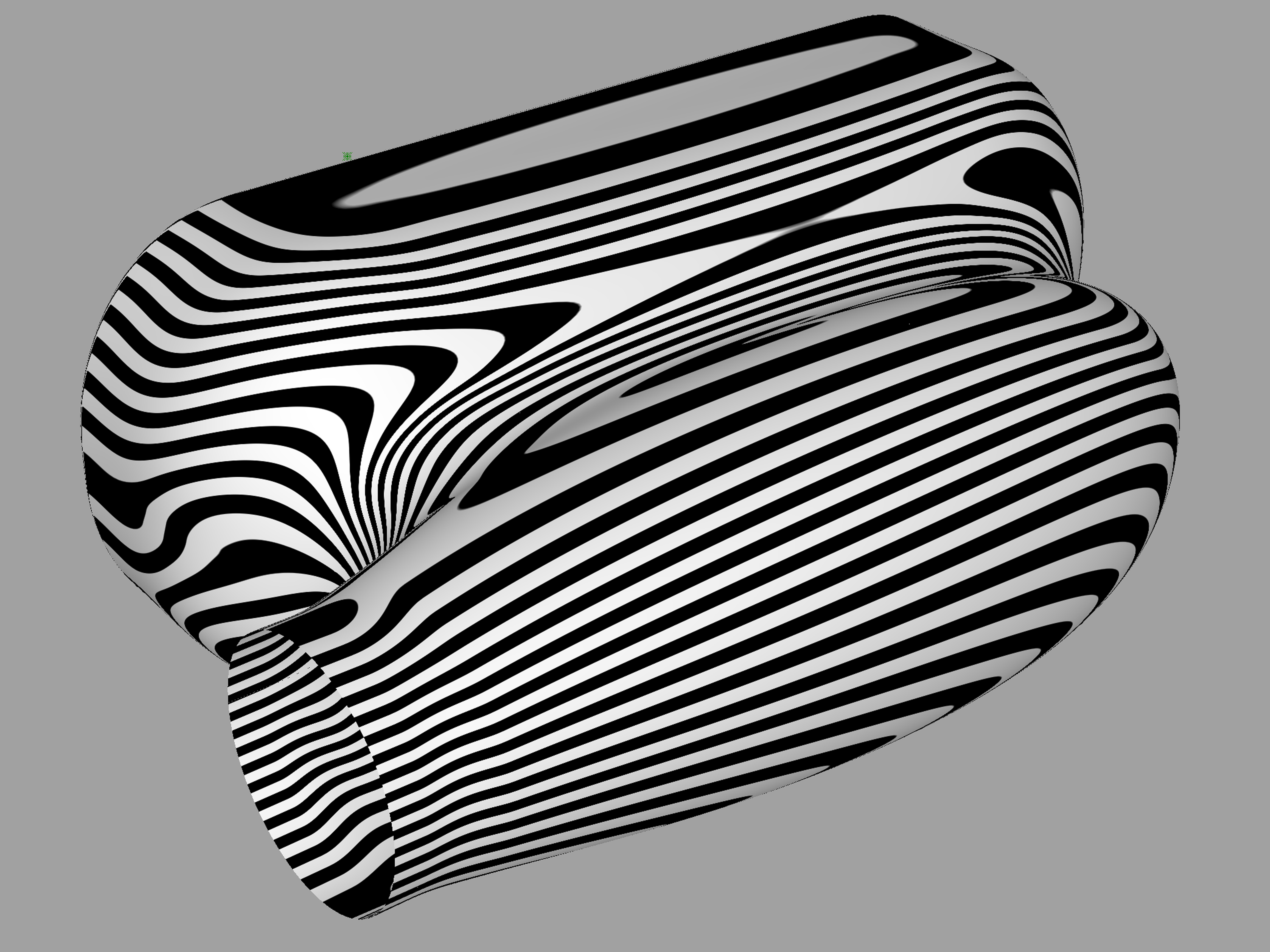

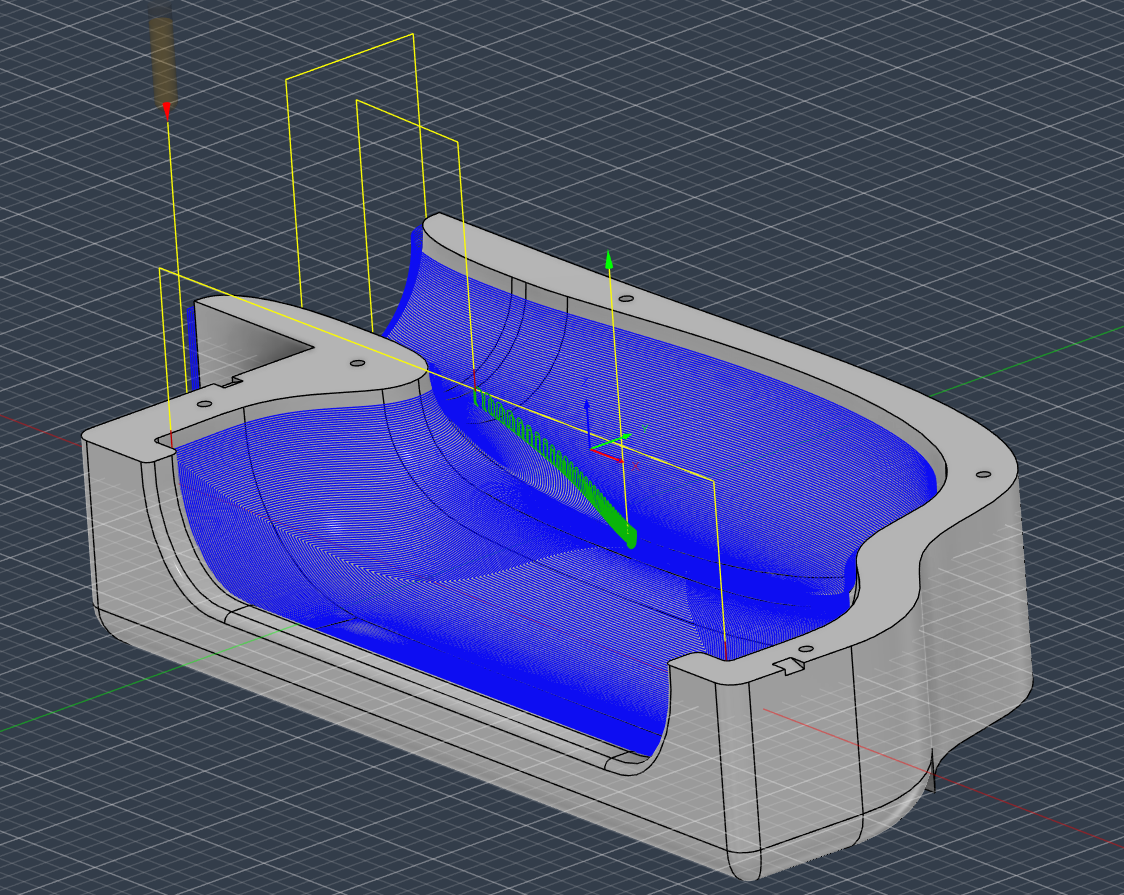

We begin by translating your ideas into CAD data. This allows for precise visualisation, dimensional analysis, and early stage refinement before any physical manufacturing takes place.

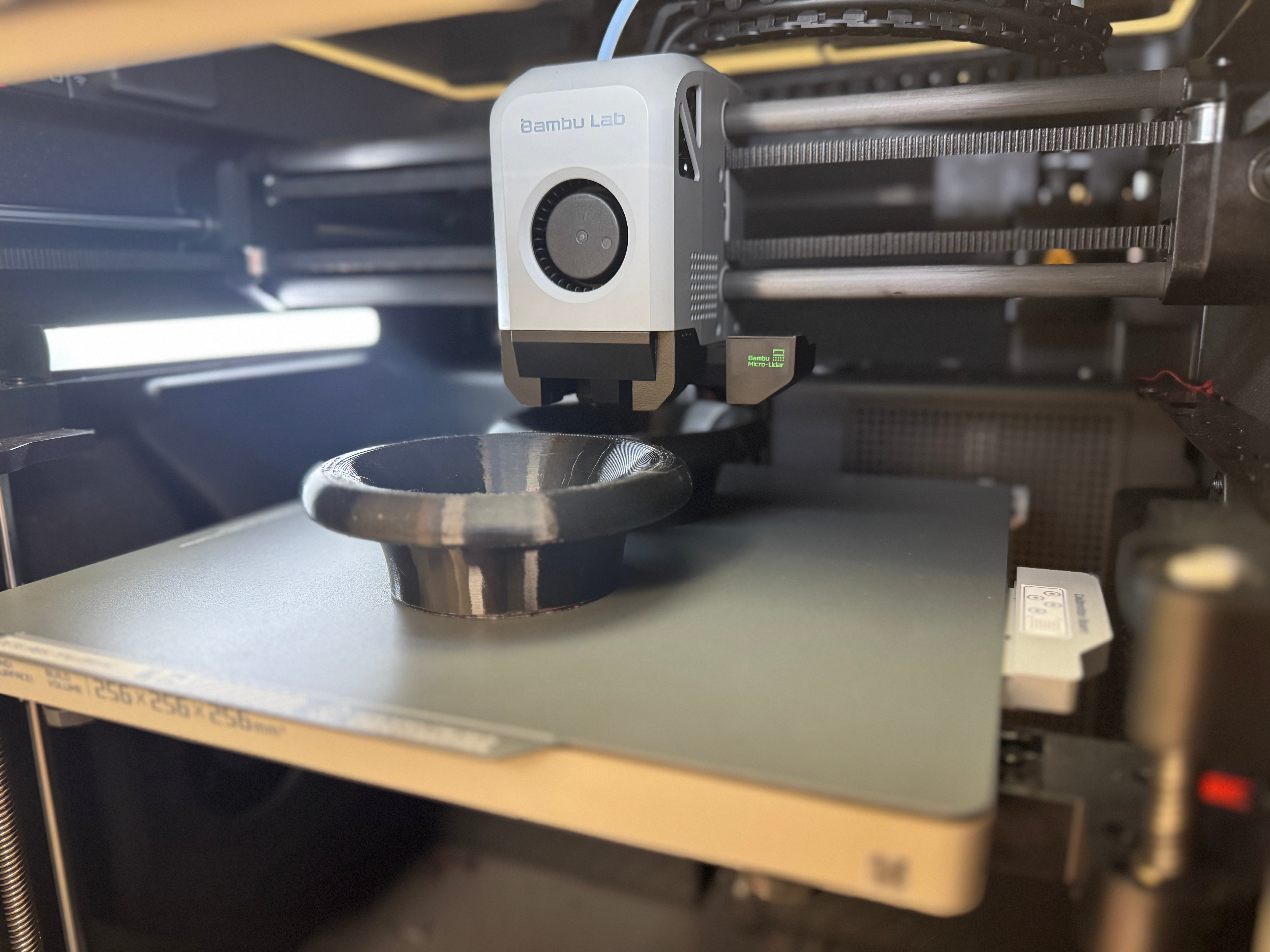

Using our in-house rapid prototyping capabilities, such as FDM printing, we can quickly produce physical prototypes. These prototypes are ideal for test fitting, form validation, and proof of concept demonstrations.

Upon finalising your concept, we initiate our manufacturing procedures, adhering to strict timelines and quality regulations. Our expert knowledge of CAM systems and our suite of 3 and 5 axis CNC mills allows us to optimise cycle times, while delivering dimensional accuracy.

For existing components that require reverse engineering, or further innovation, we offer high resolution 3D scanning services. This allows us to generate accurate data of existing parts, which can then be modelled and optimised using CAD.

We endeavour to continually innovate by closely monitoring the market for new ways to improve efficiency and quality.